SAFETY:

PLC and thermocouple feedback (hot zones, extractors, other critical areas) control temperatures to safe limits (below flash point of stamping oil).

Control loop feedback with PID guaranty stable temperatures according to recipe parameters.

OIL VAPOR:

Oil vapors are extracted by fans and condensed outside of hot zones.

PAINT FLUX:

Ready mixed Paint-F-Flux is constantly stirred in the process vessel and is supplied to spray valves by either:

PUMP: A pump in closed loop. Flow is controlled by PID and progressive valve to regulate flux flow according to recipe parameters.

PRESSURE POT: Paint flux is supplied by a pressure pot and pressure is controlled by a progressive valve.

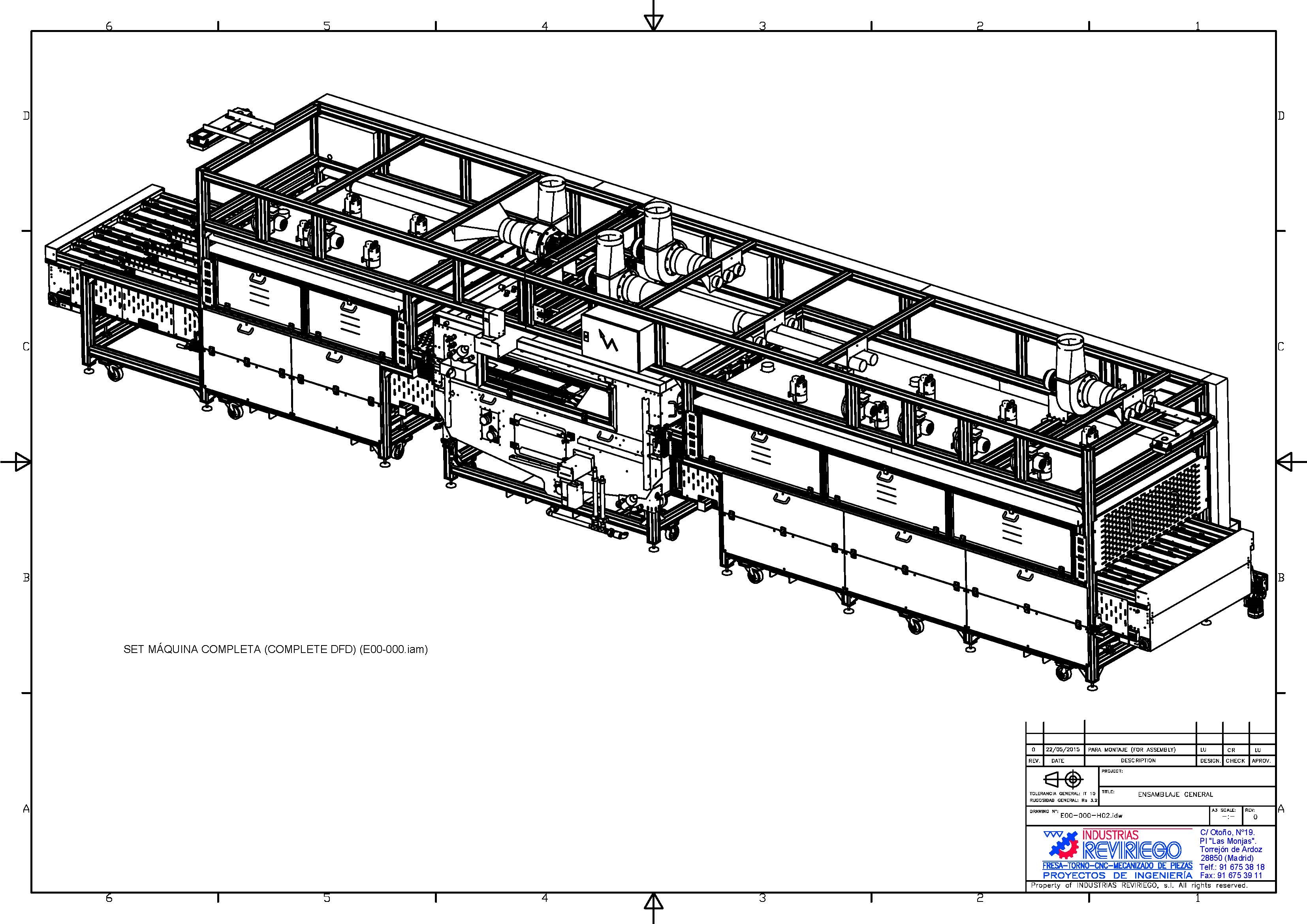

LAYOUT:

Stand Alone:

A DFD machine can be used “stand-alone” from any other equipment (to paint different kinds of components)

Integrated: it can be positioned in-line with a stamping-press (the components go automatically from the press into the DFD) or it can be positioned in-line with a tube-mill (the tubes go automatically into the DFD to be painted on both sides).